Technical Article: Plug-and-use renovation with adaptable lightweight systems

Technical Article: Plug-and-use renovation with adaptable lightweight systems

The H2020 PLURAL project proposes prefabricated, modular, and adaptable lightweight façade systems for rapid renovation of existing buildings, providing high-performance, cost-effective, and fast renovation solutions. This article outlines these technological innovations, setting out the characteristics of the three core PnU (Plug-and-Use) kits that have been tested in prototype form.

Author:

Maria Founti - Prof. NTUA, Director of Laboratory of Heterogeneous Mixtures and Combustion Systems and PLURAL Coordinator.

Note: opinions in the articles are of the authors only and do not necessarily reflect the opinion of the EU.

The PLURAL project

PLURAL (Plug-and-Use Renovation with Adaptable Lightweight Systems) aims to design, validate, and demonstrate a palette of versatile, adaptable, and scalable, off-site prefabricated plug and play facades that take into account the needs of users (‘Plug-and-Use’ – PnU kits). PLURAL is achieved through three main pillars:

- Development of three core systems, which couple heating-cooling, ventilation, heat harvesting with smart windows, 3D printing, low carbon footprint nano-enabled coating materials and smart control towards NZEB status for different European climates and various residential building typologies (<90 kWh/m2 per year of buildings’ total primary energy consumption).

- Development of a BIM-based data management platform coupled with a Decision Support Tool (DST) to optimise component selection and integration, the PnU kit design, production, manufacturing time and cost, and installation (≥ 50% reduction in the time required for deep renovation of e.g., multi-family blocks, 58% reduction in renovation costs through off-site prefabrication lean manufacturing and construction, interactively supported by the BIM-based platform and DST)

- Demonstrate the applicability of the PnU kits by implementing the solutions in three real and three virtual (replication) residential buildings to evaluate the renovation time and cost reduction, the PnU kits’ performance, carbon savings and comfort of users.

The three PnU kits (SmartWall, HybridWall and ConExWall) and their technical characteristics

High expectations of achieving a net zero energy state through deep renovation schemes require efficiently integrated HVAC systems and RES, as well as full exploitation of heat recovery and passive systems. Smart windows, nano-enabled coatings and adaptive control systems also play a crucial role in the energy balance and optimisation of the multifunctional kits.

The three PLURAL core systems are based on commercial components which are extended and flexibly combined with HVAC, RES, and control strategies to create the innovative PnU kits. They are linked together to create technological systems capable of fulfilling the specific demands in different climates and building typologies.

SmartWall: External/Internal air heating and cooling system

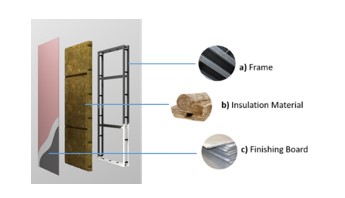

Figure 1. General view of SmartWall

Figure 2. Core components of a typical SmartWall

The SmartWall PnU kit has been developed by project partner AMS as a multifunctional wall system that combines active with passive technologies, including fully prefabricated walls, high-performance windows, balcony doors, slim-type fan coil for heating and cooling, split units, air ducting systems, radiators and convectors, PV panels, batteries, and control and fire protection systems. It is a compact versatile prefabricated kit which can be installed externally or internally (in case there are space or aesthetic restrictions) in existing building envelopes, introducing an innovative, dynamic, and flexible retrofitting solution reducing installation time and construction faults. The SmartWall is easily adjustable to any dimension up to 4m of height per module and can be decorated with any kind of finishing material. It is appropriate for all building types and climatic conditions, while it is more effective for climates with a significant cooling demand.

Figure 1 illustrates its three basic components, which are the frame, insulation material, and finishing layers. The SmartWall frame can be easily manufactured using materials such as steel, timber, industrial plastic, aluminium or carbon fibre. This flexibility allows production of a large variety of panel sizes with various frame strengths. Possible insulation materials are rockwool, glass wool, EPS, cellulose and VIP (backside of a convector). The finishing surfaces of the SmartWall can be chosen according to its internal of external application, such as boards made of cement, gypsum, fibre, timber, metalbond, etc. In the frames used in the PLURAL project the finishing surfaces are treated with PCM-multifunctional coatings enhancing the self-cleaning, IR reflective, anti-bacterial, self-healing etc., characteristics. These were produced by project partner AMS. Almost all materials are selected with respect to their thermal and environmental-friendly credentials.

As a modular Plug-and-Play panel (Figures 1 and 3), the SmartWall is constructed containing flexible piping and electrical wiring connections that can accommodate either the existing or a new heating/cooling system and electrical services (switches, plugs etc.). This significantly reduces the on-site installation time. Photovoltaics can be part of the external SmartWall or can be installed on the roof of the building if the geometry includes balconies or volumes that shade the vertical external surfaces.

Figure 3. General example of a Smartwall application.

The manufactured PLURAL prototypes incorporate slim-type fan coils, air ducting systems, PV panels, batteries, control and fire protection systems. The kits are combined with high performance triple pane low-e windows with mechanical ventilation and heat recovery (70%). These features are enough to convert the renovated building towards NZEB status. Windows can also be combined with smart blinds for optimum visual and thermal comfort conditions. 98% of the materials used in this solution are recyclable and eco-friendly, only the air purification filters cannot be recycled.

The HybridWall with Air Handling Unit

Figure 4. General view of the HybridWall

The HybridWall is a versatile, adaptable, scalable, off-site prefabricated Plug-and-Use kit, based on the patented Denvelops® Hybrid Textiles System. It is composed of vertical stainless-steel guide lines and connectors, that allow the kit to be attached and bear the loads of the cladding (Fig. 4). The thermal insulation is made of mineral wool and is protected by a weathering layer. Both are attached to the system vertical guidelines in order to achieve the required thermal and water-tightness performance. The mineral wool is covered by a glass-fibre layer that can protect against mechanical damage. The system includes at least 50% of recycled material. The cladding of the façade is made with painted aluminium cladding tiles and a resistant powder coating. PV panels are integrated in the façade, replacing the final cladding.

The main innovative HVAC component integrated in the HybridWall is the Air Handling Unit developed by partner CVUT. The unit is located in a vertical position. This incorporates two-stage heat recovery, the first being a plate heat exchanger, the second is an active heat exchanger with thermoelectric modules and provides supply air temperature control. The unit is connected with the interior space via supply and extract channels. Due to maintenance reasons, the ventilation unit must be located next to a window side (Fig. 5).

Figure 5. Air Handing ventilation unit and air channels (left) and PV panels (right) in HybridWall

The manufactured prototypes are composed of two sequences of three frames, each of which has been designed to pre-install, transport, and facilitate the final installation of the following features:

- Smart Window: The window unit is safely preattached to the frame during assembly and transportation, then guided and installed to its final position, completely detached from the hanging façade and perfectly sealed. The window finishings are designed to allow access to the maintenance filters of the unit ventilation. The smart window has been provided by the Italian partner of the project consortium, Bergamo Technologies.

- Shading system: The louvres are placed in front of the windows and allow the interaction of the occupants to provide total lighting and shading.

- Air Handling Unit developed by partner CVUT,The ventilation unit is safely preattached to the frame during assembly and transportation, then installed to its final position, completely detached from the hanging façade,

- PhotoVoltaics Energy harvesting: Specifically designed PV panels produced according to the Denvelops requirements.

- Insulation: Innovative components allow not only the pre-installation of the insulation layer to each frame and transportation but also the final fitting on site.

- Specific cladding design: The innovative technology ‘SNAP attachment’ of Denvelops Hybrid TexTILES easily installable façade, due to its screwless installation.

This prototype has allowed trying out the newly developed components, assembly, and installation procedures for the functionalities described, and will allow further testing on the components’ usability, acoustics, and thermal performance of the solution.

ConExWall: Prefabricated timber façade integrating external wall heating and cooling system

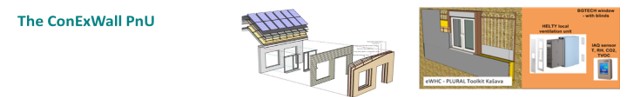

Figure 6. General overview of ConExWall

Figure 7. Heating layers in ConExWall

The ConExWall is specifically designed to be used in colder climatic zones, such as continental and alpine locations. The fundamental material for the frame is timber because of its low carbon footprint, high flexibility in shape, dimensions, and variety of connection techniques. It integrates a heating/cooling pipe network in its composition (Figures 6 and 7) yielding a dynamic HVAC feature.

The advantage of this heating concept is the thermal activation of the whole existing façade which allows for using the existing wall as thermal storage. In case of a heating system with a heat pump and PV, this enables running of the heat pump longer and to higher temperatures during times of excess electricity gains from the PV system, and on the other hand, to run it for shorter times during periods when electricity must be purchased from the electricity grid. Additionally, such an operational mode overcomes shortage of energy delivered to a room, which is strongly dependent on the opaque external wall area. An integrated control system, by means of an advanced monitoring system, measures weather data, the supply temperature of the heating system, room temperature, and CO2 concentration and will control the thermal comfort as well as the IAQ.

The outer layers serve as load bearing timber and include the main thermal insulation. Its purpose is to ensure the best and maximum contact of the heating/cooling pipes with the existing façade wall accounting for wall irregularities. This enables the element to adapt to uneven sections of the wall. After investigations, the most appropriate materials were selected that include the group of organic (wood fibre, sheep wool, hemp wool) and mineral (glass and rock wool) materials. The heating/cooling pipe network is constructed with standard materials of radiant floor heating systems.

Figure 8. ConExWall concept visualization.

The ConExWall can easily integrate a local air-handling unit with heat recovery in order to supply fresh air to a single room (Fig 8.). Additionally, it is ready to integrate above or below the kit module-integrated windows with mechanical ventilation system, including heat recovery integrated in the frame of the windows or in the new façade.

Technology and Kits’ requirements

The parameters and requirements, which determine the application of PLURAL core technologies in each building could be summarised in the following categories:

- The location of building (climate conditions, heating and cooling demands),

- The building geometry and restrictions (type, height, Window to Wall Ratio - WWR, balconies, historical façades, architectural & structural projections & recessions, maximum permissible insulation thickness),

- The energy performance of the building envelope (U-value, thermal mass, heating and cooling systems),

- The structural capacity and behaviour of the existing building (load bearing capacity, movement behaviour, seismic design limitations, adjacent to building joints treatment, etc.).

Table 2 provides an overview of the minimum parameters and requirements and limitations of the PnU kits. All the PLURAL PnU kits can be applied on almost every type of residential building (single family, terrace, multifamily and apartment) and in almost all climatic zones. In any case PLURAL’s PnU kits must meet the national Building and Health and Safety Regulations (e.g., mechanical stability, safety in use, fire and seismic behaviour, acoustic, waterproofing and durability).

The demonstration sites and selection of PnU kits

The PLURAL PnU kits are planned for real and virtual applications to verify their design and performance in various residential building typologies and in different climate zones in Europe (Table 2). Each real demonstration building faces different challenges and objectives given by the local legal requirements, owner plans, inhabitants’ expectations, etc. The purpose of the demonstration is the technical, environmental, and financial viability of the deep retrofitting to ensure NZEB status, while also validating cost and renovation time.

The characteristics of the three demonstration sites where the three core PnU kits will be installed are:

Czech pilot – Kašava

The Czech pilot project in Kašava is a detached double dwelling house built in 1962. Renovation does not only include improving the thermal insulation of external walls and windows and the installation of renewable energy sources. The Czech strategy for the building energy efficiency retrofit prefers complex solutions for the whole thermal envelope. The ConExWall is not used only on outer walls, but modified prefabricated elements are used on new walls and roof construction. The volume of the roof is changed to improve internal flat distribution and to minimise the surface of external thermal envelope. New volume has been designed to avoid thermal bridges that are joined with the traditional mode of energy efficiency refurbishment.

Regarding HVAC, the existing gas boiler will be replaced by an air-to-water heat pump as the heating and cooling source for the ConeExWall integrated system. Integration of a BIPV system on the roof is essential to achieve NZEB. Also, each room will be equipped with a local ventilation unit with heat recovery.

Spanish pilot – Barcelona

The Spanish pilot project in Barcelona (Terrassa) is a renovation of one of two blocks of residential social housing built in 2008. The project meets the specific requirements of the building owner to improve the management of the building and to match with the user needs. These requirements are at the technical, social, economic, and building control level. The final scenario involves renovating the East and West façades of the selected building block using the HybridWall, counting it as an intervention to the thermal envelope, as well as using the roof area facing East in order to install photovoltaic panels for RES generation, using the same PnU solution as for the façade, but without affecting the thermal properties of the roof. Important emphasis is on the installation of new windows with outer folding blinds and external air handling ventilation units for each apartment.

Greek pilot – Voula-Athens

The Greek pilot project in Voula, Athens is a multi-floor residential social dwelling for elderly people built in 1971. The local municipality divides the overall renovation in two stages, mainly for budget reasons, as well as, to minimise the relocation of tenants to other buildings (as the building provides accommodation to elderly people with limited financial capabilities). The first renovation stage works in the semi-basement and ground floor have been completed since September 2020. The second renovation stage is focused on the external envelope of the building; roof renovation and insulation; refurbishment of the apartments, common areas, corridors, staircases, lifts etc.

Application of the Smartwall PnU kit aims to refurbish and upgrade each apartment with recyclable and eco-friendly materials in order to reduce energy consumption to reach the Greek KENAK NZEB standard (5) and ameliorate the thermal, acoustic and visual comfort of the residents. The SmartWall upgrade includes an air-to-water heat pump for heating, cooling, and DHW systems, and solar thermal collectors for DHW and a PV system on the roof.

PLURAL achievements

PLURAL demonstrates the successful integration of passive and active systems into one hybrid kit and their ability to work together in synergy for façade retrofitting, reaching NZEB. It creates best practice renovation examples for the residential sector based on innovation and competitiveness, with benefits for citizens and the environment.

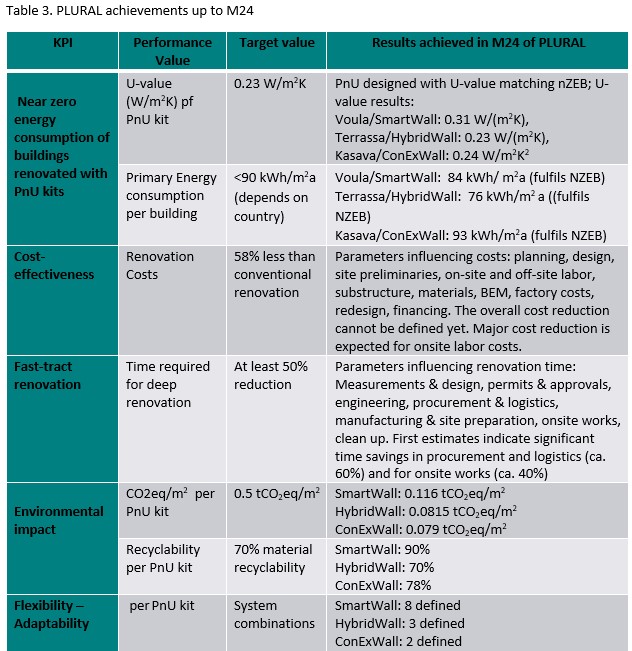

Table 3 summarises the project achievements up to M24. They include expected energy savings and present indicative KPIs that characterise the operational performance of such off-site fully prefabricated hybrid Plug-and-Play kits for deep residential building renovation.

Developments, fine tuning of performance parameters, and monitoring of the demonstration sites will continue until September 2024 (M48 of the project).